Tags

- accounting

- administration

- Ambulatory Surgical Center

- anesthesia

- anesthesia residency

- anesthesiologist

- anesthesiology

- ASC

- board of directors

- board of directors data analysis

- business

- CEO

- cfo

- chairman

- cmo

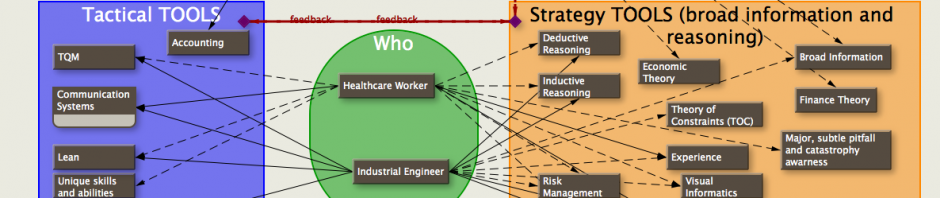

- concept graph

- concept map

- constraints

- constraint theory

- COO

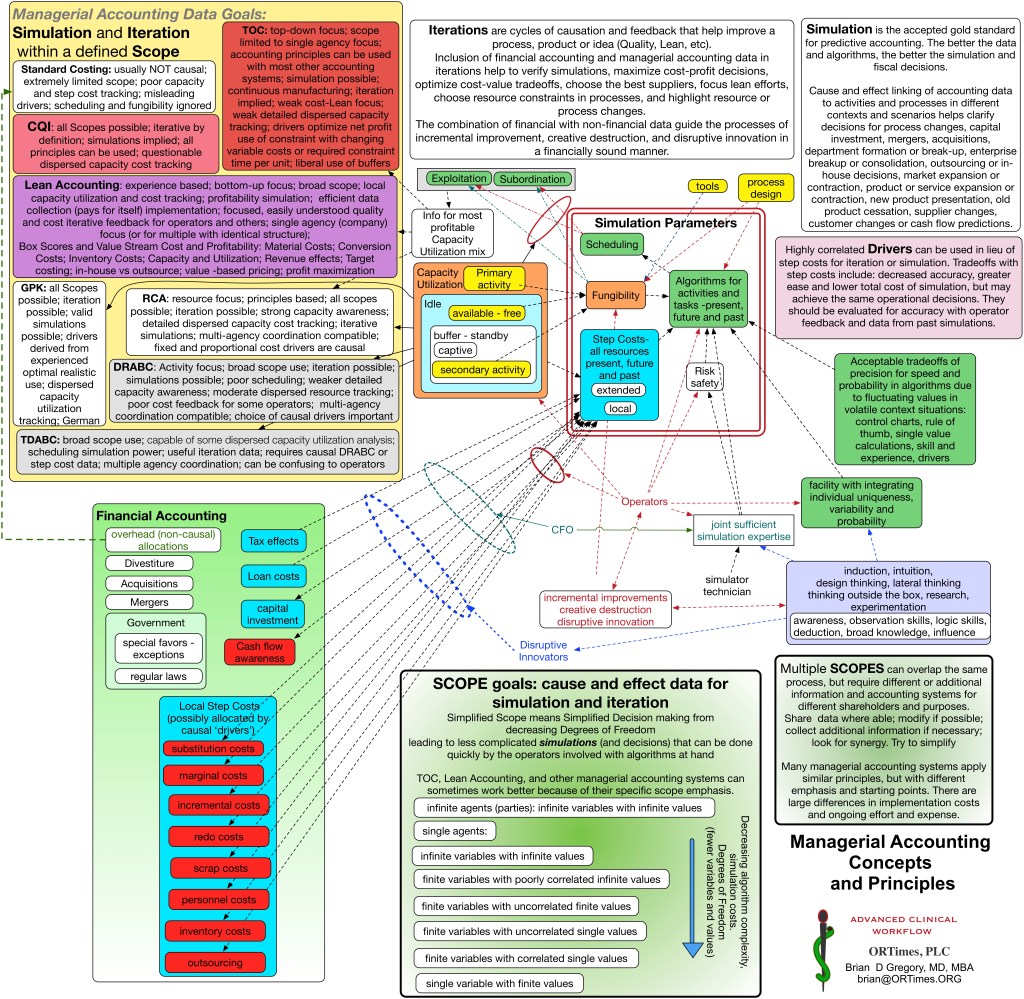

- cost accounting

- CRNA

- decisio

- decision algorithm

- deparment chairman

- dissatisfaction

- emotional intelligence

- finance

- flipping

- flip room

- FTE

- fungibility

- healthcare reform

- healthcare systems analysis

- healthcare systems engineering

- hospital

- hospital patient flow

- incentives

- information technology

- legal risk

- nurses

- operating room

- operating room efficiency

- operating room productivity

- operating theatre

- operations m

- operations management

- OR

- OR scheduling

- OR throughput

- PACU

- preOP

- revenue sharing

- risk

- risk management

- room flipping

- satisfaction

- schedule

- scheduling

- spc

- sqc

- surge

- surgeon

- surgery

- surgical case

- systems analysis

- systems engineering

- theory of constraints

- throughput

- throughput accounting

- toc

- TOT

- turn over time

- vice chairman